ASSEMBLY TECHNOLOGY

THE RIGHT MACHINE

FOR EACH PROCESS

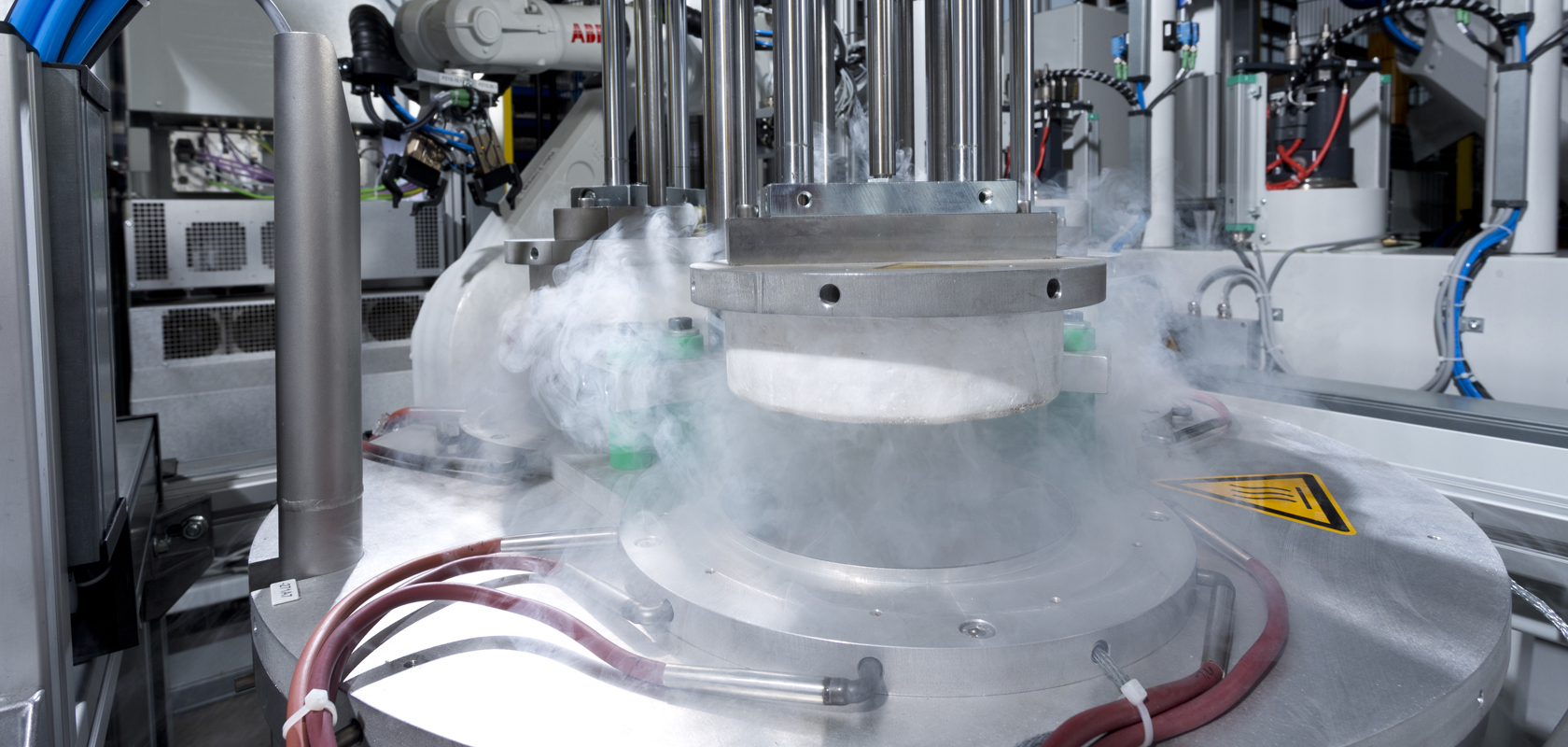

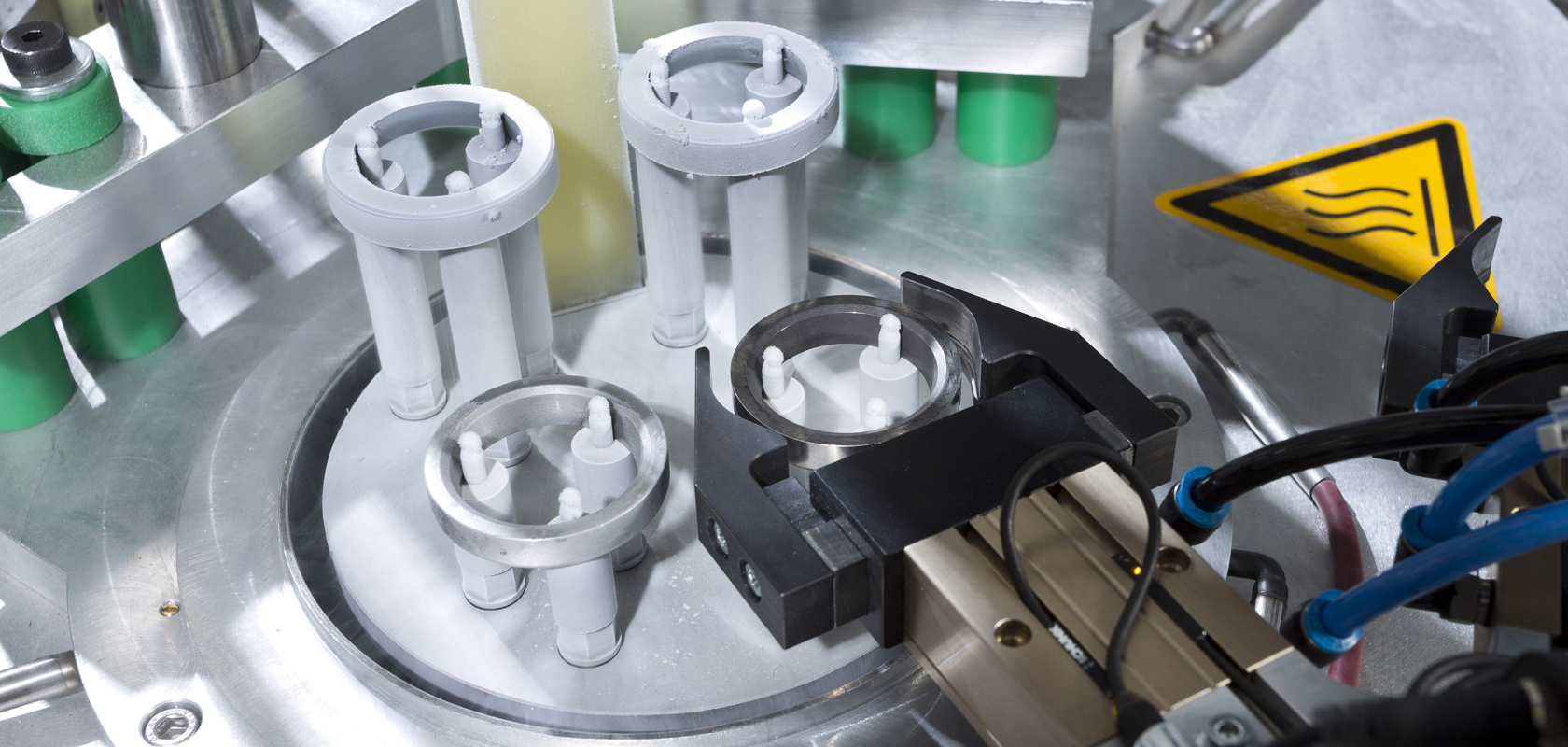

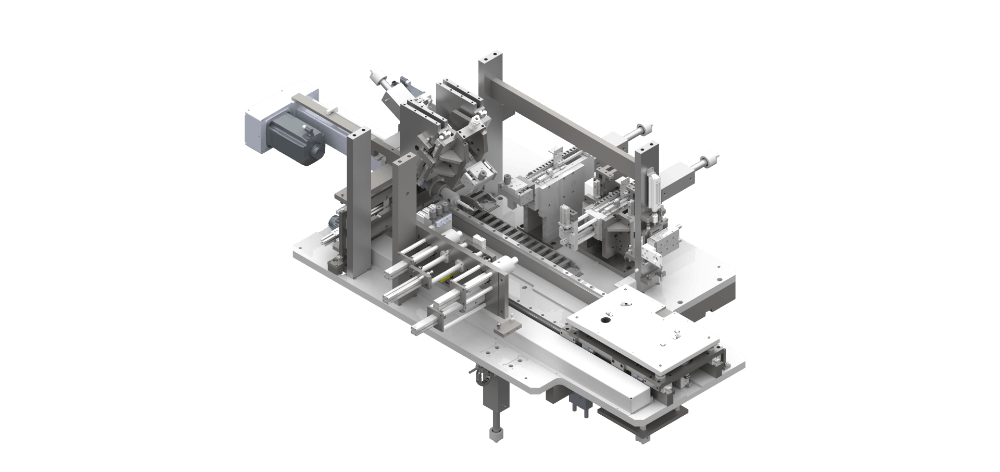

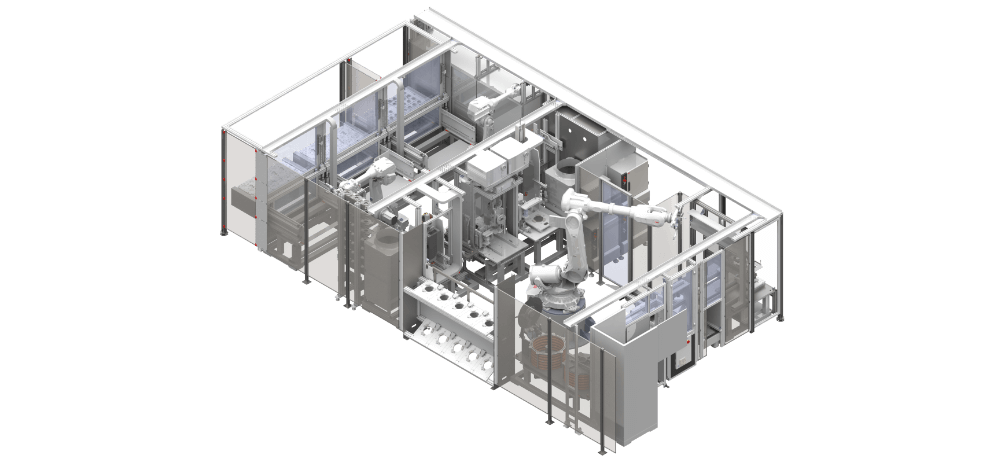

Whether before or after leak testing, there are many assembly steps in a production line. Each component has its own requirements for assembly steps, cycle times and methods. Coping with this requires specialized equipment that will accurately perform all necessary operations. And that is what we provide.

ASSEMBLY TECHNOLOGY

PROCESS UNDERSTANDING MEETS CREATIVITY

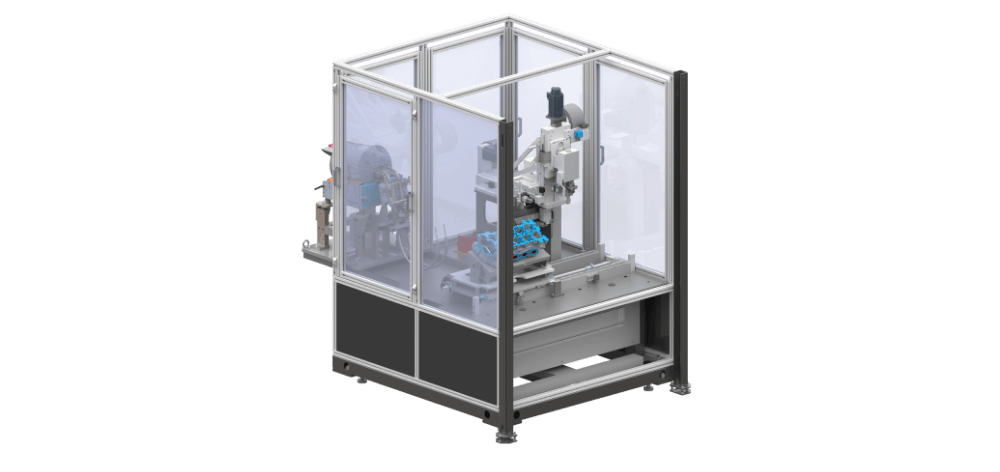

Assembly lines are always very specific systems. As complex as assemblies and their associated components are, so are the machines, assembly steps and logistics behind them.

That’s why our assembly cells are as individual as your component assemblies. With creative approaches, which are based on in-depth process understanding and decades of experience, we develop and build custom tailored assembly machinery.

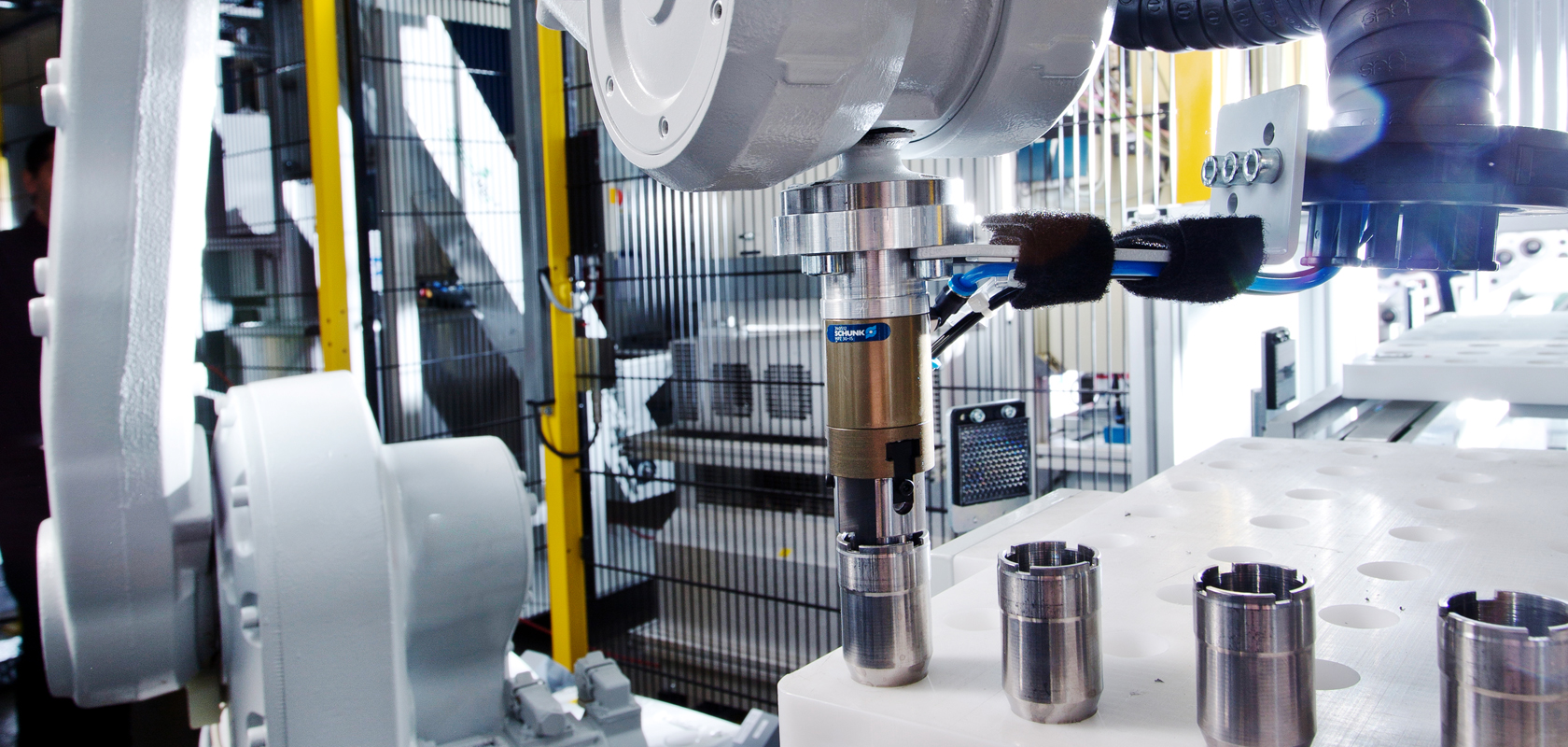

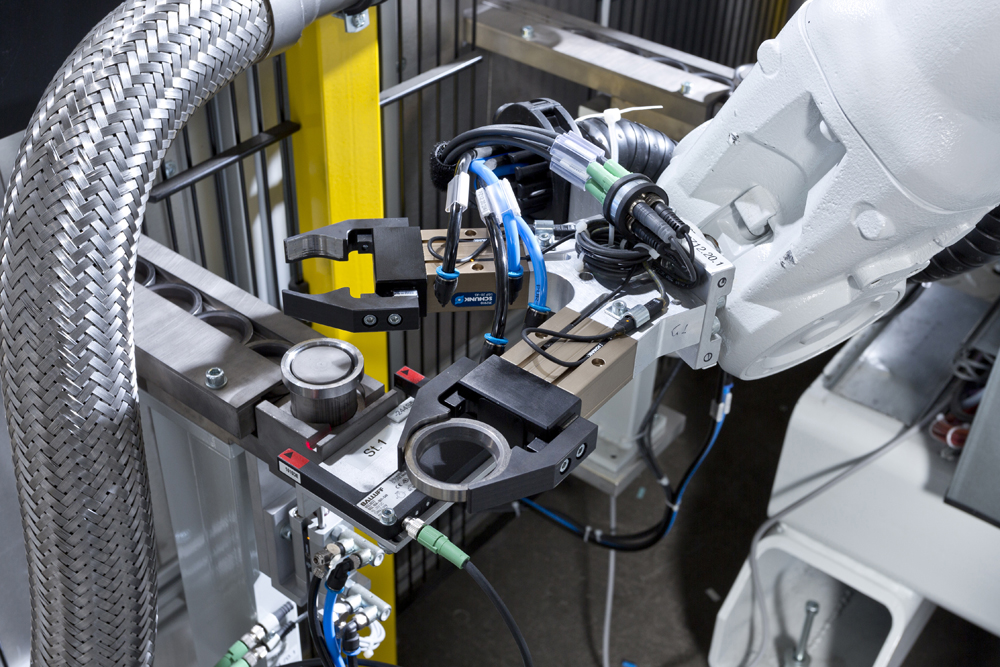

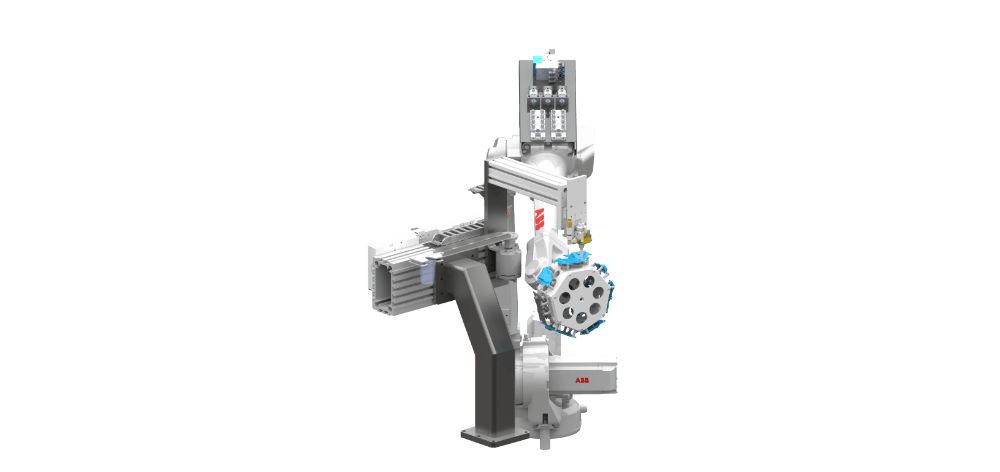

We develop micro- and macro-processes, program robots or linear servo axes, construct individual operations and redundancies, and ultimately bring everything together based on your requirements.

Assembly steps are fundamentally component-specific, and they can be automated as needed using custom robotics.

COMMON ASSEMBLY PROCESSES

CONTACT

WOULD YOU LIKE TO KNOW MORE ABOUT OUR ASSEMBLY SOLUTIONS?

From non-binding inquiries to specific advice, we are at your disposal.

ADDITIONAL INFORMATION

LEARN MORE

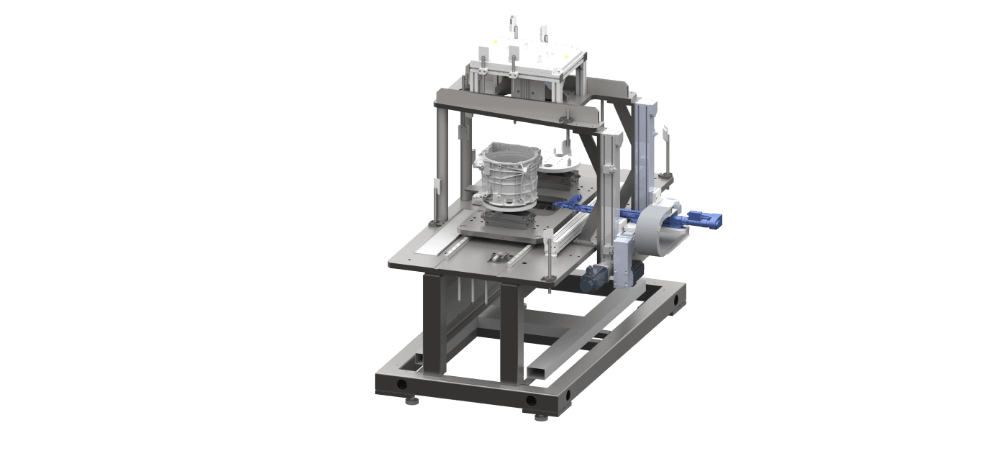

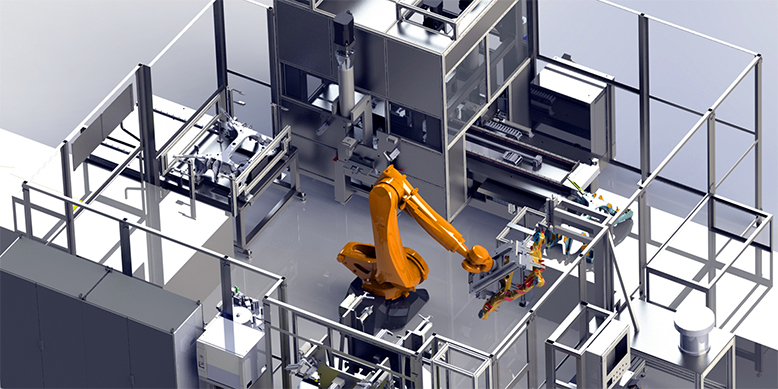

REFERENCE: AUTOMOBILE FRONT&REAR BRACKET ASSEMBLY

In this project for the front and rear brackets of automobiles, we designed a highly flexible production line and applied a variety of assembly processes.

Click here to learn more

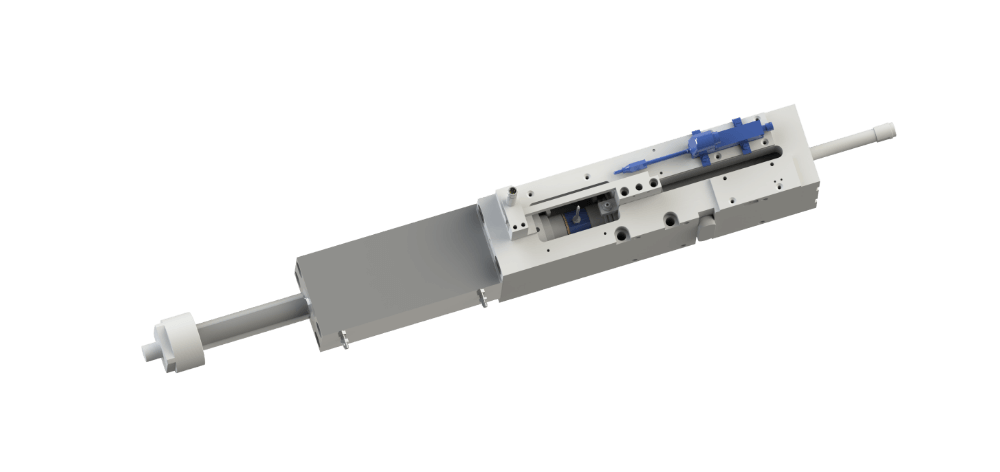

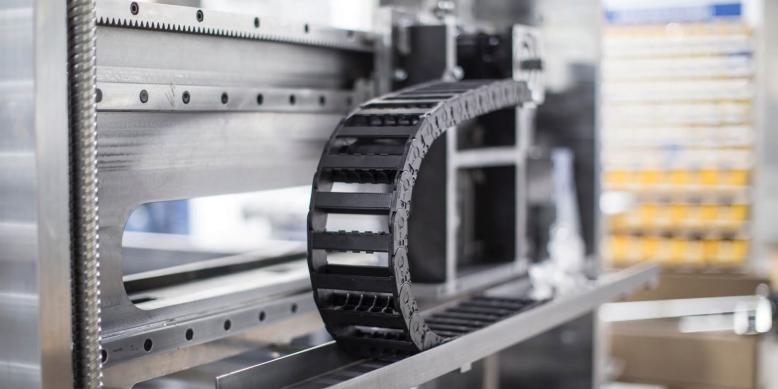

OUR MACHINE DESIGN

Our machines are characterized by robust, solid construction, which has proven equal to the task of continuous industrial use over the years.

Click here to learn more